There is a small company who developed a very cool device with an embedded processor. To speed their prototype development effort, the company used a commercial-off-the-shelf (COTS) processor board. This processor came with an open source operating system and some convenient interfaces, which allowed the designers to use the same processor for software development. They made a nice looking enclosure for the device, found a compatible power supply, and quickly assembled something they would be proud to show a potential investor.

Unfortunately, after all that hard work, they realized they needed an analog input that they didn’t have. It was for a volume control knob, which they felt would greatly improve the user experience. At the time they were shopping for the processor board, they didn’t realize they needed that analog input. Consequently, although being very careful to select something powerful and flexible, they picked something that fell short in this small, but important area.

Here’s how they solved the problem. They added another processor, one that you don’t see often in commercial prototypes. They added an Arduino Duemilanove. Yes, the Arduino is one of the processors you see advertised in electronic hobbyist

e-zines. Hobbyists love these devices, because they are inexpensive and easy to use. Well… guess what? Professionals also love devices that are inexpensive and easy to use.

They could use Arduino, because the original COTS processor had an extra USB interface. At first, the idea of using an Arduino to provide the analog interface received resistance. They were told, “You don’t understand the complexities of the USB protocol stack.” And “This approach will take too long to code up. “

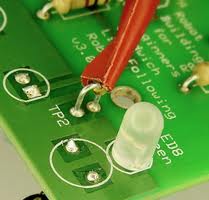

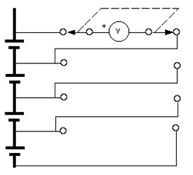

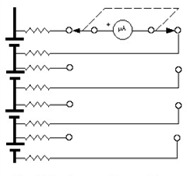

So they took a little time to investigate the approach. This is what they found. It was easy, so easy, in fact, that they were able to demonstrate the solution in less than 4 hours. They connected a little potentiometer up to the Arduino with three wires. That was that easy. They found a pre-written script for sampling an analog input and transmitting those samples over the Arduino’s USB interface. And that was easy. They downloaded and installed the Arduino development software and then loaded the Arduino sampling script into the Arduino. Next, they connected the Arduino to the COTS processor. They had to write a little shell script to run on the open source operating system to see their results, but that was easy too. This was just another serial device as far as the operating system was concerned.

What was really nice was that the Arduino got its power through the USB interface. So, it was not necessary to provide another voltage source to power the Arduino.

Also, since the Arduino is small, they could fit it inside the existing enclosure.

In the field of rapid prototype development, you need to be creative, and you need to think out of the box. But most of all, you need to be quick. If you’re taking too long to implement the next wiz bang device, you might just be allowing your competition to beat you to the market. That can mean missing a grand opportunity. The company realized this, and they did what needed to be done.

After the accomplishment, the team jokingly claimed “we have just constructed the world’s most expensive volume control knob,” but they all knew the truth. When it comes to prototype development, time is money, and this was the least expensive way to achieve the desired result and still make their schedule.

copyright 2013 NetChime Research, LLC, All rights reserved.

http://www.netchime.com